Energy Saving Insulation

.jpg) The fibreglass wool loft insulation that most of us have in our loft has largely been replaced by modern PIR foam on flat roof construction which is very good, 100mm thick foam has about the same insulation as 300mm ( 1 foot ) thick old loft insulation. There are several manufacturers are KINGSPAN and CELOTEX they both have web sites that explain all about it in great detail

The fibreglass wool loft insulation that most of us have in our loft has largely been replaced by modern PIR foam on flat roof construction which is very good, 100mm thick foam has about the same insulation as 300mm ( 1 foot ) thick old loft insulation. There are several manufacturers are KINGSPAN and CELOTEX they both have web sites that explain all about it in great detail

If you are having your flat roof replaced it makes good sense to upgrade the insulation at the same time as this may be the only practical time to do so.

Insulating a flat roof can deliver real benefits, a warmer room in the winter and cooler in the summer as it works both ways, lower energy bills and improved carbon emissions. Current building regulations can mean that insulation upgrade is compulsory to create Energy Efficient Roofing.

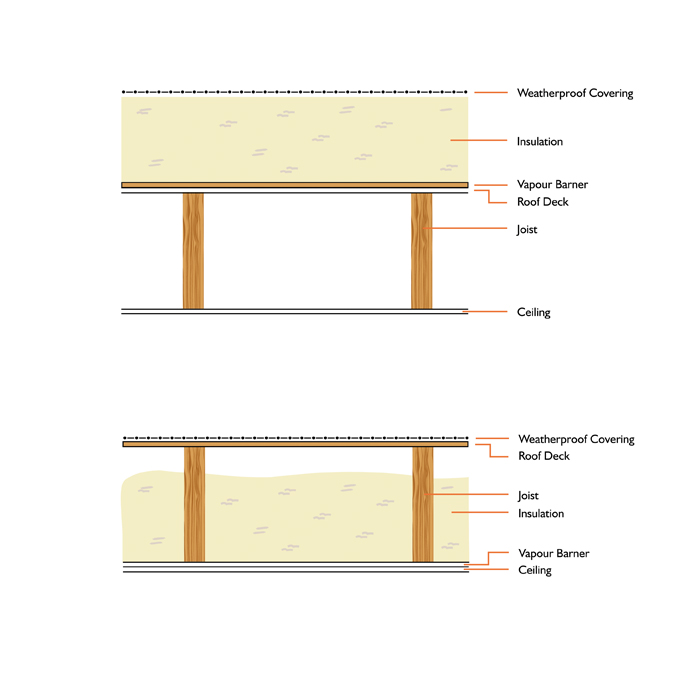

There are essentially two methods of construction used in insulating flat roofs, the older method called Cold roof deck (fig 1) and the current recognised method called Warm roof deck (fig 2) explained below

COLD DECK

This is the most common form of construction but is also the least thermally efficient.

From the ceiling up the build up is as follows. The roof joists support the roof and the internal ceiling is attached to the underside, between the supporting joists the voids fibreglass wool insulation is laid in most cases its only around 4” thick, In buildings constructed in the 60s, 70s, 80s, this is most likely way the roof has been insulated in the roof void. On top of the joists the roof deck is fastened and the waterproof covering is laid

WARM ROOF

This is the current up to date method of insulating a flat roof construction and is advised to be used when ever possible, although not all roof structures can accommodate this design. This method is particularly useful on roofs with smaller structural supporting timbers such as Dormer type roofs. From the ceiling up the build up is as follows, the roof joists support the roof construction and the internal ceiling is attached to the underside, on top of the joists the sub deck is fastened. A vapour barrier sheet is then laid over the deck. And the appropriate thickness of insulation is fastened to the roof sub deck and now the waterproof layer can now be installed. A big benefit of this method of insulating is that it alleviates the formation of condensation in the roof void, and complies with current building control regulation.

Energy Efficient Roofing